Your advantages – overview

Fast and low priced production without loss of quality

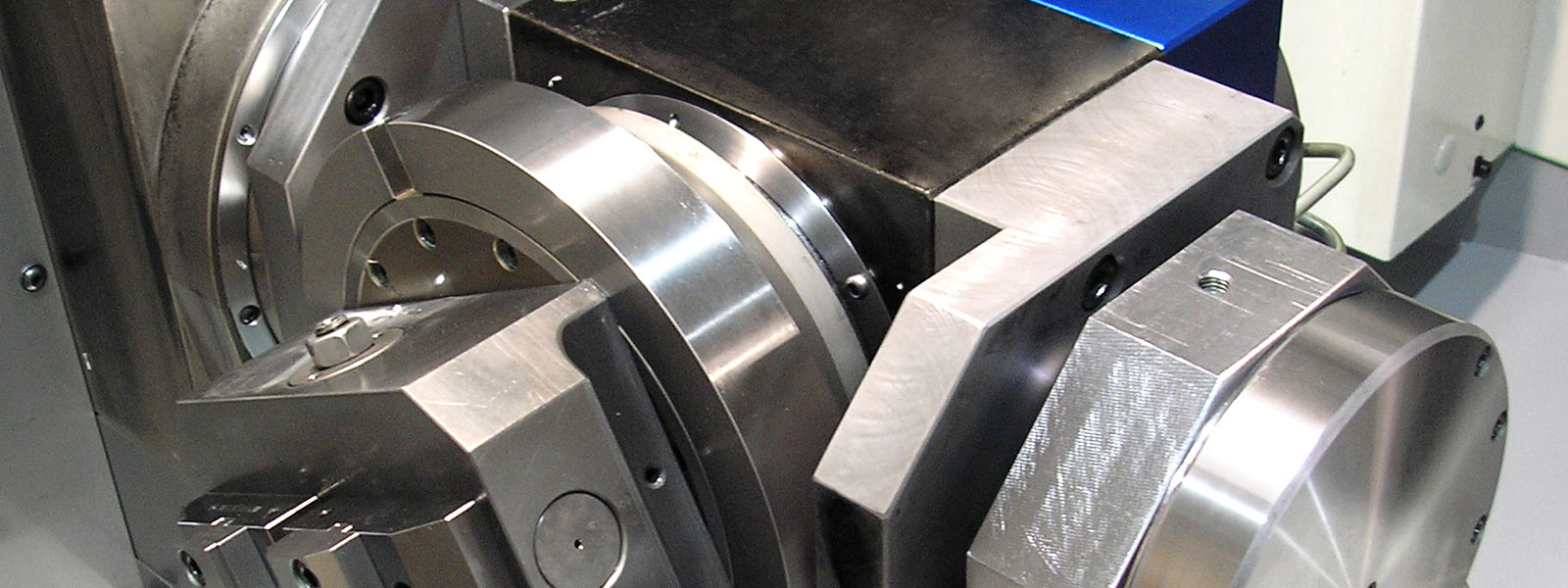

Using CNC dividing heads and rotary axes on required applications will put you in a position to increase your machining capabilities with an additional 4th or 4th/5th axis. We offer you the possibility to achieve your specific machining task in an efficient, productive and cost-effective way, by using our up-to date range of equipment.

Advantages of multi-face machining

- Reduced number of settings guarantees reliable geometrical accuracies between each machining step

- Positioning inaccuracies due to multi setting are not applicable

- Better processing sequences e.g. with cross over (e.g. cross holes…)

- Increased productivity due to shorter cycle times, setting times and work-piece handling

- Increased efficiency and reliability because of a lack of uncontrolled handling-time

- Less clamping positions reduces the cost of the required fixtures

Advantages of our dividing heads and rotary axes

- Significant reduction of non-production time

- High cutting efficiency due to rigid and at the same time compact design

- No hydraulic components and service requirements (gear driven units only)

- No additional clamping system required (gear driven units only)

- Our CNC dividing heads and rotary axes are easy to interface mechanically and electronically in existing systems

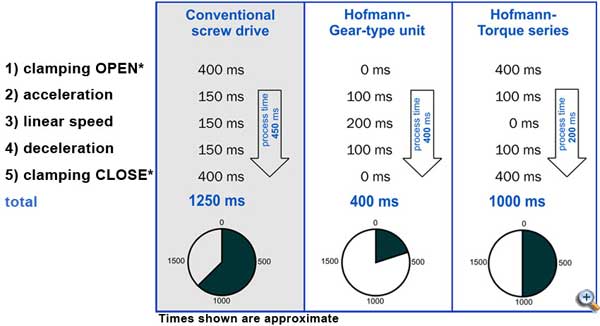

Comparison of non-productive times for a positioning cycle of 90°

* times for clamping system “open” and “close” result in the sum of enabling time set in the control system, times for the switching of the valves and time consumption until the required hydraulic pressure is achieved, etc.

Approximately 90% of all HOWIMAT CNC dividing heads are manufactured and delivered without an additional clamping system, because the patented recirculating ball gear offer exceptionally high torsion stiffness.

Only approximately 10% of all HOWIMAT CNC dividing heads require an additional hydraulic clamping system, normally only for the following applications:

- clamping of the counter bearing on tilting axis (depending on the application, rotary axis requires no additional clamping)

- clamping of the counter bearing when using swivelling bridges or applying extreme tangential forces during machining