Our Howimat gear-type units in practical utilisation

CHIRON FZ 15 high-speed

(vertical machining centre with separate loading and machining area)process:

5-face machining of various components

dividing head:

CNC 160/160.2/A2 (4 and 5 axis)

- including Vischer & Bolli Dock Lock system 3 to for different fixtures

- including rotary-distributor with 2 outlets for rotary axis

- including clamping system for the counter bearing (750 Nm)

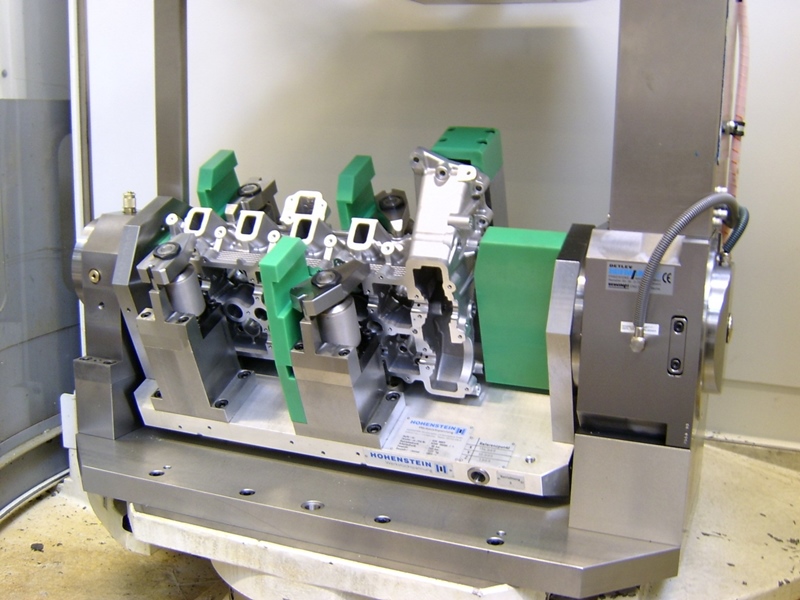

DECKEL-MAHO DMP 60V

(vertical machining centre with separate loading and machining area)process:

5-face machining of various components

(serial parts, 2 pieces in one setting)

dividing head:

CNC 160/160.2/A2 (4 and 5 axis)

- including rotary-distributor with 2 outlets for rotary and tilting axis

- including clamping system for the counter bearing (750 Nm)

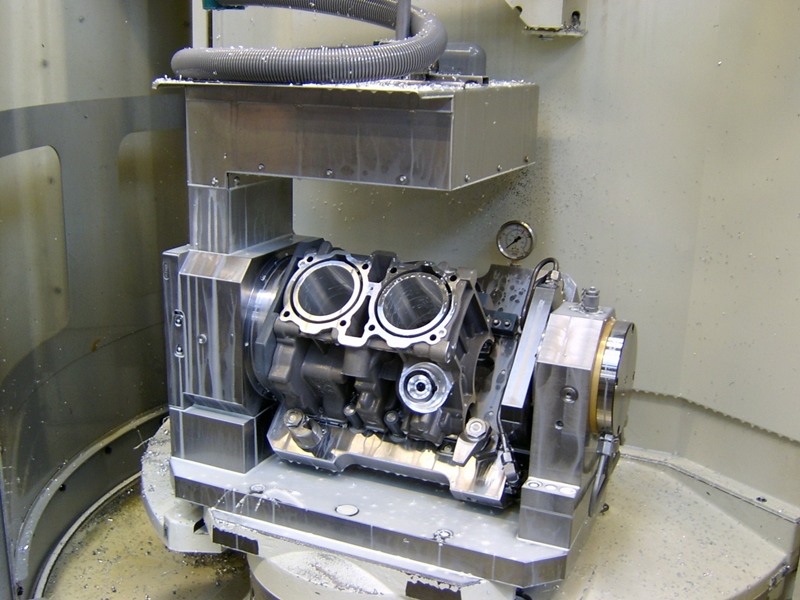

HELLER MC 25

(horizontal machining centre with X = 800mm)process:

drilling and milling application on cylinder heads

dividing head:

CNC 220.2/K (4 axis)

- centre height 250 mm, with baseplate 290 mm

- including rotary distributor with 4 outlets

- including swivelling-bridge, clearance 570 mm

- including clamping system for the counter bearing (900 Nm)

- including direct measuring system

HELLER MC 25

(horizontal machining centre with X = 800mm)process:

drilling and milling application on steering box including 3-dimensional drilling appl.

dividing head:

CNC 160.2/Z2-A400 (4 axis)

- 2-spindle dividing head with spindle distance 400 mm

- including 2 swivelling-bridges, clearance 760 mm

- including clamping system for the counter bearing

- including 2 quick-change clamping systems

- including automatic loading

HELLER MC 16

(horizontal machining centre X = 630mm)process:

drilling and milling application on cylinder housing

dividing head:

CNC 220.2/Z (4 axis)

- centre height 210 mm, with baseplate 250 mm

- including rotary distributor with 3 outlets

- including swivelling-bridge, clearance 350 mm

- including clamping system for the counter bearing (900 Nm)

- including direct measuring system

CHIRON FZ 08 KS Magnum

(compact vertical machining centre with X=450mm and Y=270mm)process:

5-face machining (2 work-pieces with approx. 200 x 40 x 100 mm)

dividing head:

CNC 160/2Sp125.2-A230 (4 and 5 axis)

- twin-spindle tiltable dividing head

- lowered rotary axis

- spindle distance 230 mm

- fixture diameter 229 mm

- including 2 rotary distributors with 2 outlets for rotating and tilting axis

- without spindle clamping system

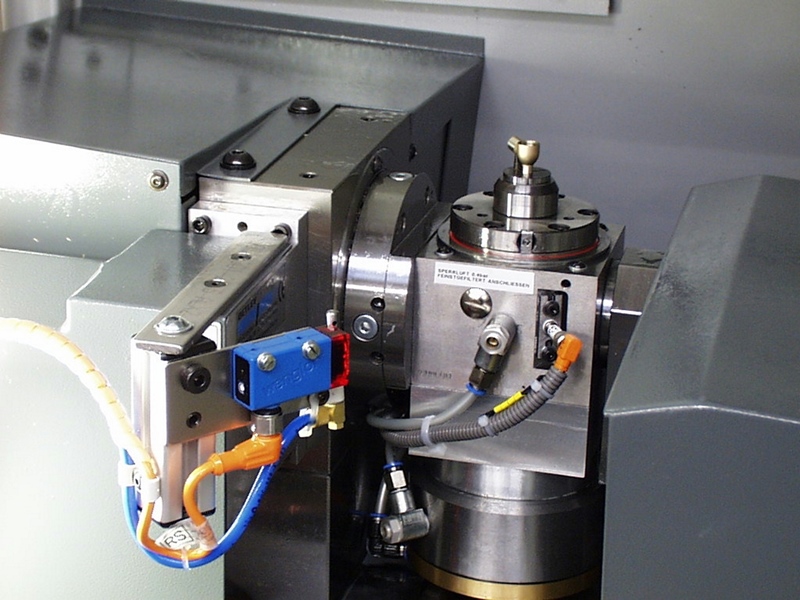

CHIRON FZ 08 KS

(compact vertical machining centre with X=300mm and Y=250mm)process:

5-face machining including 3-dimensional drilling application

Milling and turning operations!

dividing head:

CNC 160/80.2/A2/HS (4 and 5 axis)

- gear reduction switchable from

i = 30 for milling operation to

i = 1,5 for turning operations - including automatic collet-chuck for W20 collets

- including direct measuring system for rotating axis

CHIRON DL 18 KL

(twin-spindle vertical machining centre)process:

5-face machining for various parts up to diameter 180 mm

dividing head:

CNC 220/4Sp160.2-A200 (4 and 5 axis)

- 4-spindle tiltable dividing head

- spindle distance 200 mm

- spindle bare 80 mm

- lowered rotating axis

- including counter bearing clamping system 1.250 Nm

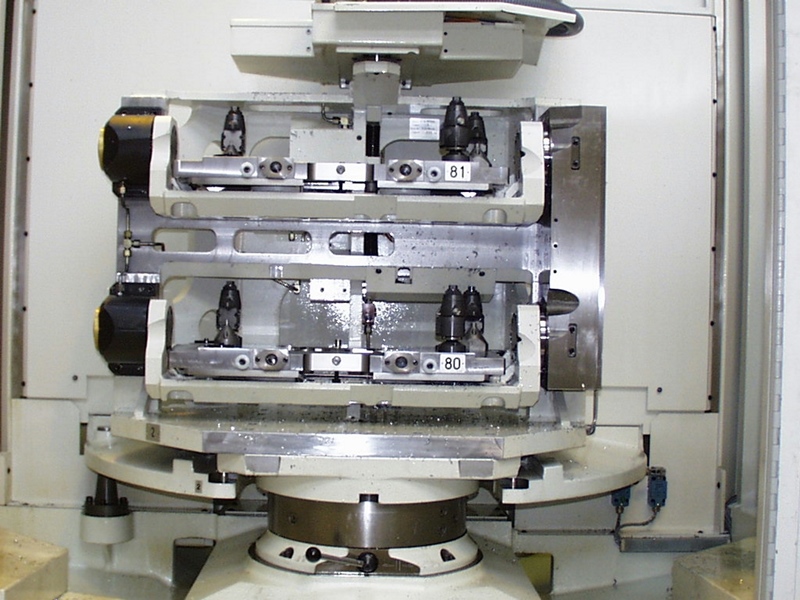

CHIRON FZ 18 L 2000

(vertical machining centre for twin-table machining)process:

drilling and milling operations with multipiece fixtures

dividing head:

CNC 160.2/Z (4 axis)

- 1 unit in left hand and 1 unit in right hand design centre height 215 mm

- including fixture plate 700 x 350 x 50 mm

- swiveling base plate with clearance 640 mm

- including hydraulic rotary distributor for 2 outlets

FANUC 0iC

(wire-cut EDM machine with robot loading system)process:

EDM machining of PKD-tools up to 300 mm length

dividing head:

CNC 125.2/K-NIRO (4 axis)

- non-corroding dividing head

- sealing according to IP 68

- automatic HSK-63 clamping system

- suitable for robot loading

- true surface runout < 0,001 mm

- including direct measuring system

SODICK MC 430 L

(compact HSC-machining centre)process:

5-axis machining of various components (mould and die production)

dividing head:

CNC 125.2/K-80.2/K/A2 (4 and 5 axis)

- tiltable 2 axes dividing head

- including face plate 45 mm

- with lowered rotating axis

- rotating distributor with 2 outlets for automatic chuck EROWA IST 100

- all connections of the rotary axis are lead through the tilting axis